Additional information

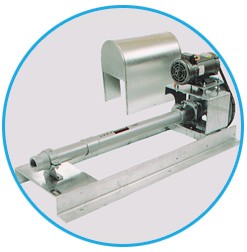

| Features | CT201 A ‘quick release access port allows the cutter assembly to be maintained in-place without removing the equipment and therefore reduces maintenance time. Rotational speed produces high torque, resulting in lower operating power at 1.5 or 2.2kW, which are available with energy efficient motors. Lower cutter tip speeds dramatically reduce wear rates. Slow speeds also ensure low noise and vibration, and good abrasion resistance. The off-loading requirements for ‘on-stand’ tankering are matched by the Munchers capacity. Pull-back cutter stack allows removal without disturbing the pipeline. CT203/205 Mono ETOS cutters offer positive and effective solids maceration. Shafts operate at differential speeds to promote a tearing action on the solids. Pull back cutter stack allows removal without disturbing the pipeline. Cantilever shaft design eliminates the need for bottom bearings and seals, significantly reducing wearing components. Patented built-in trash trap with clean-out ports to catch any rejected material. Low cutter tip speeds, low power and low noise level. Each Muncher is supplied with a programmable logic controller (PLC) to protect the machine against damage and overloads. Munchers can be supplied to comply with the ATEX Directive 94/9/EC. |

|---|---|

| Warranty | Please check Mono’s website for Warranty information. |

| Brand | Mono |